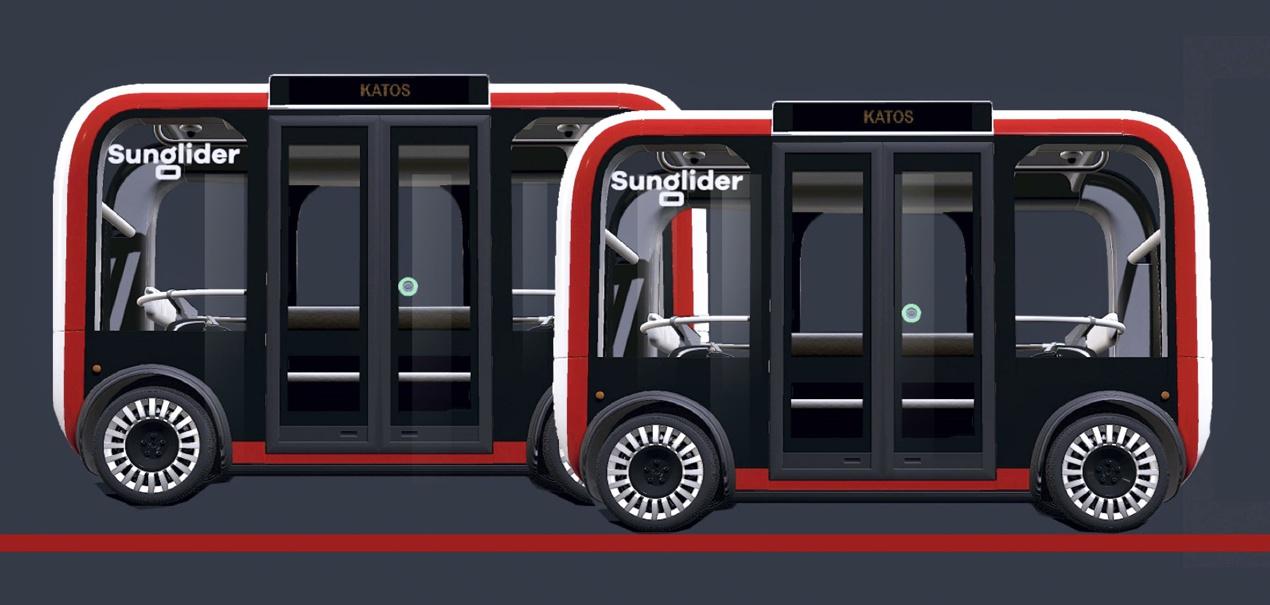

Katos

The Sunglider Metro has the most advanced public transport vehicles in the world. The vehicle system is a further development of the revolutionary, crowd-designed, autonomous shuttle bus »Olli«, which is produced by Local Motors in Chandler, AZ/USA. The Sunglider shuttle version is called KATOS (=below) and carries up to 12 passengers.

The vehicle is not a vision. It has been manufactured in a highly revolutionary way since 2016 (see additive manufacturing). On the road, it is powered by four 20kW electric motors and moves autonomously on pre-mapped routes with a fully functional Level 3+ system, dynamic obstacle avoidance, emergency stop and manual takeover capabilities, and a sensor configuration for a maximum field of view. Sunglider passengers use the vehicle where it is available or book it via the Sunglider app.

Panos

The bigger sister of the little KATOS is the glider »PANOS« (=above).

PANOS is 8 meters long and is a people mover for 25 to 30 passengers. The PANOS also runs autonomously with a customized AI version of KATOS, because controlling a driverless suspension railway is much easier than doing so on the ground level. PANOS has a revolutionary photoelectric drive (see FE drive).

The wheel assessment of the PANOS is taken from a co-development of the outstanding wheel-assessment-technology of large roller coasters and is driven by sixteen 20 kW motors. The wheel optics taken from the KATOS serve as a noise blimp, which guarantees a whispering driving noise thanks to the proactive noise suppression technology the metro uses!

Cargo

The Sunglider freight vehicle called "CARGO" is a transport glider for courier, express and parcel-logistics (CEP). CARGO is 8 meters long and can transport 20 Euro pallets. It preferably operates during off-peak times (also at night due to the whisper drive).

The CARGO glider should be an alternative or a replacement for the growing number of small courier, express and parcel trucks. CEP logistic companies may use the Sunglider stops as distribution centre for the last mile of (bicycle) delivering during the day. Each stop will also have an automatic parcel pick-up station.

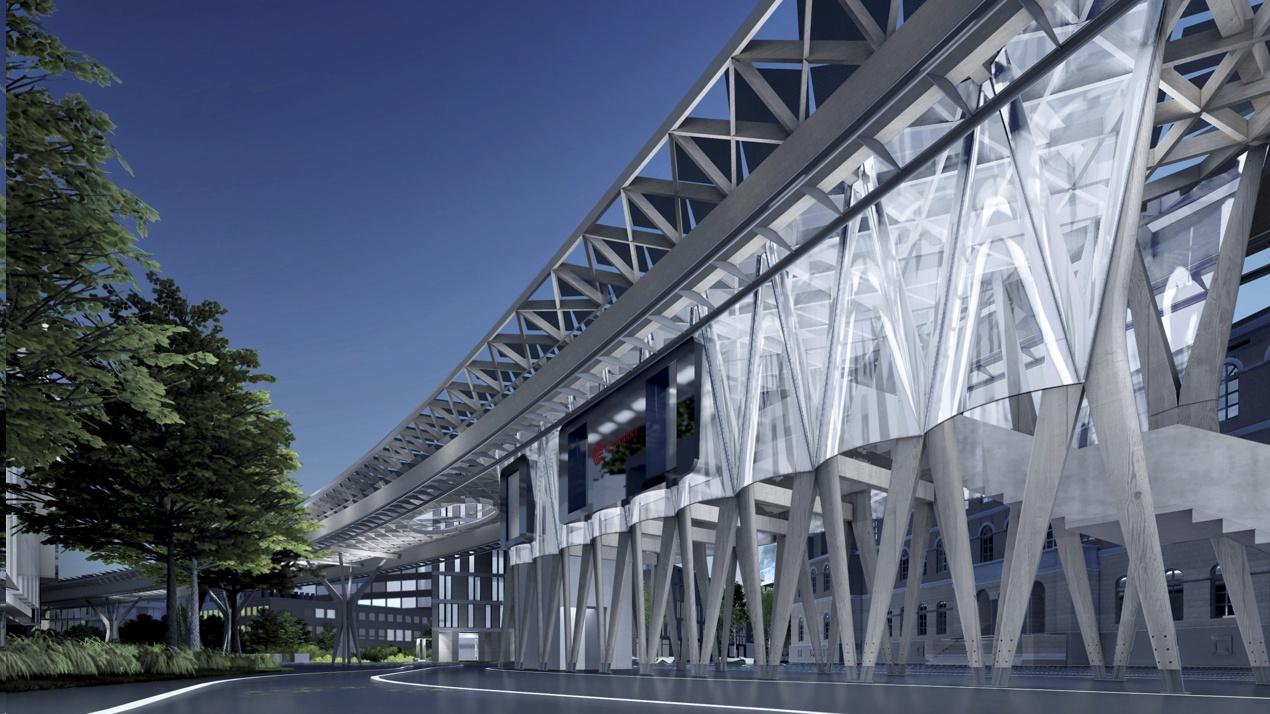

The pylons

In fact, the Sunglider stations & constructions are a sensitive intervention in any cityscape. In order to increase acceptance, the architecture must be sustainable, appear transparent and look like organic forms. That is why we see the main components of the elevated railway, the pylons, as avenue trees, or better as metaphors for avenue trees, carrying the railway's loads with their outstretched arms. That gives the pylon construction a very special charm.

All pylons are made of glued laminated timber, a material that has been used for decades for wonderful, large and elaborate wooden constructions (see the EXPO 2000). All pylons consist of identical individual parts that can be quickly assembled, set up and replaced. This is how the Sunglider route is created as an avenue of tree pylons that form the Sunglider’s typical »Xylo-Solar-Route«. (from »xylos«, Greek = wood).

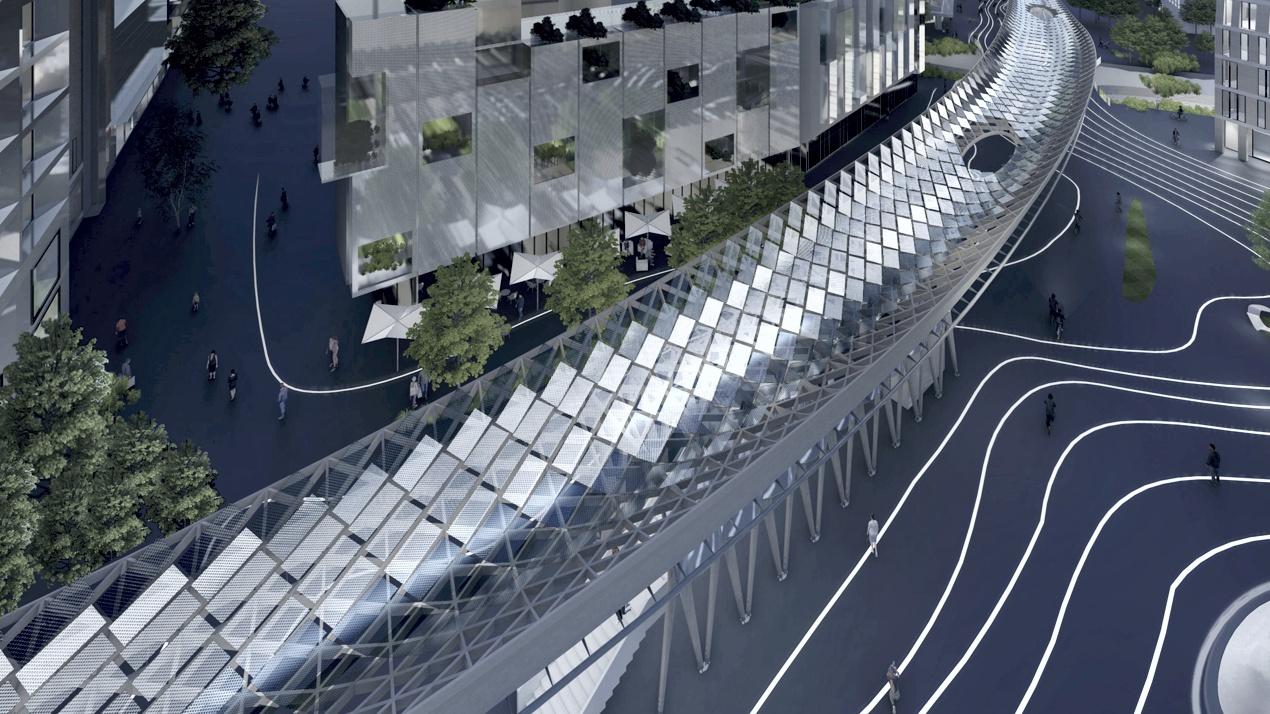

The solar roof

A Xylo-Solar-Roof, also made entirely of glued laminated timber, towers above the pylon avenue like a giant treetop. The roof covers the entire route by 6 meters and will be made of open honeycomb patterns that emphasize the character of the roof as a treetop. However, the roof is not designed to be rigid. It adapts to the respective conditions of the streets and can also be narrower or wider than 6 meters. The solar roof owes this flexibility to high-performance, parametric computer tools.

The main function of the roof, however, is to be used as the metro’s solar power plant over the entire length of the route, to convert sunlight into electricity - and to power the Metro photo-electrically.

The stops

The Metro gliders have a stop every 700 meters. The stops are small »island-stations« where the PANOS gliders dock stably at the security doors. The stops are usually to be found at the crossing points of the streets. The stops are covered by the solar roof, too, and assure a significant contribution to the metro’s energy generation thanks to their larger surface area. The outer walls of the stops are designed to mirror the surrounding architecture and make the construction »disappear« somewhat behind the facades.

Each stop is designed to be barrier-free thanks to innovative, cost-effective and functionally stable elevators. The mobility hub will be located under each platform, where KATOS and e-bikes await the passengers. The CEP pick-up stations for citizens are also located in the metro’s Mobility Hub.

The »photo-electric« fuel

The solar power plant of the Sunglider route consists of hundreds of thousands of PV modules. They have an output of 250 MW or 340,000 HP, which corresponds to the output of 4000 VW Golf cars (85 HP). This massive amount of energy is the metro’s photo-electric fuel, the "fairy dust" the Sunglider runs on. A special highlight: the (direct) current is generated directly where it is consumed i.e. by the eight 20 kW direct current motors of every vehicle. That is why the Sunglider does not need any expensive inverter technology.

The vehicles' super-capacitors are directly charged by induction at every stop. There is no vulnerable overhead line. No loss of energy, either. A welcome side effect of the solar roof is the free street lighting, which we imagine as light bands in the ground.

Additive Manufacturing

The three-dimensional (3D) printing of goods of all kinds is referred to as »additive manufacturing«. In this process, automatic printers add the material to a work piece layer by layer; the printers "add up" so to speak, and continue to do so until the product is completed. Additive manufacturing has many positive effects. Among other things, costs and production times are drastically reduced.

The Sunglider vehicles will all be printed fully automatically and controlled by AI computer algorithms. The printed parts and components are assembled by hand and by small robots. All vehicles are printed from natural composite materials and are 100% recyclable. Sunglider vehicles are not scrapped, but shredded and then reprinted.

Micro-Factories

We call this qualitative leap in industrial manufacturing »Industry 5.0«. Robots, 3D printing and networked machines are revolutionizing production everywhere. Instead of transporting goods at great expense, only data are exchanged digitally and globally, from development to production. This allows Sunglider to manufacture the vehicles on-site, in micro-factories no larger than traditional workshops, with no supply chains. The PANOS, KATOS & CARGO vehicles are produced and serviced at home in small numbers, cost-effectively and according to requirements.

They are also serviced in the micro factories. The supply of raw materials and materials is primarily solved through recycling. This saves a huge amount of energy and resources and it leads to very low manufacturing costs for the vehicles and a very small ecological footprint at the same time.